Lyftteknik och materialhantering i världsklass

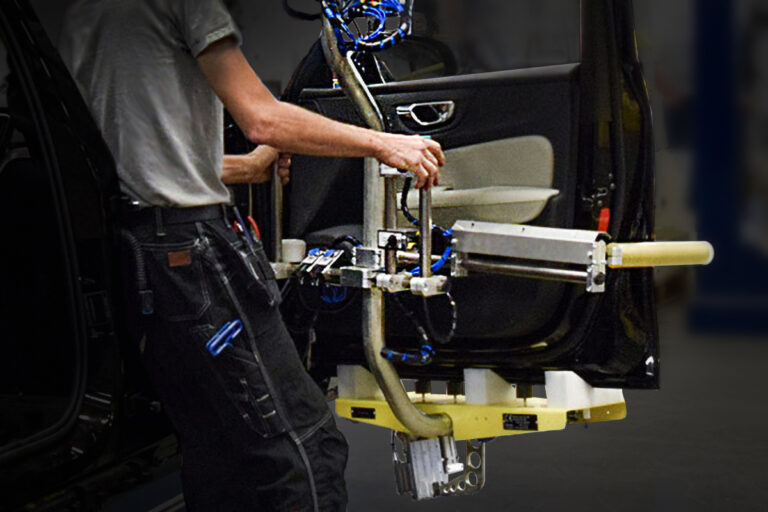

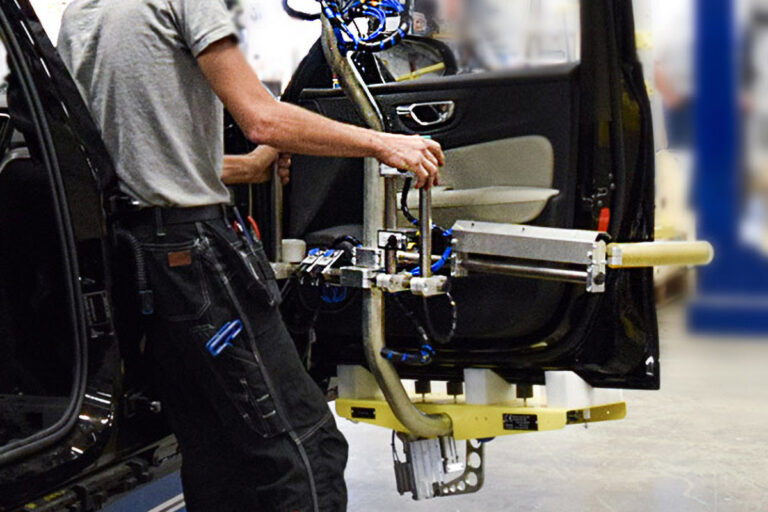

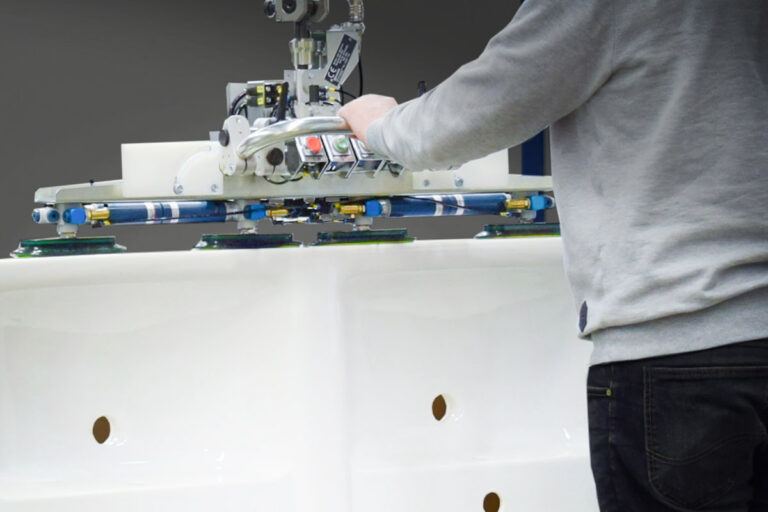

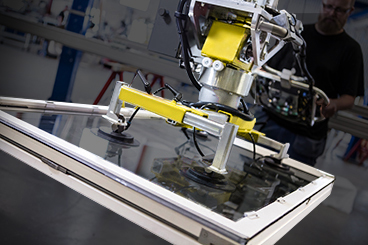

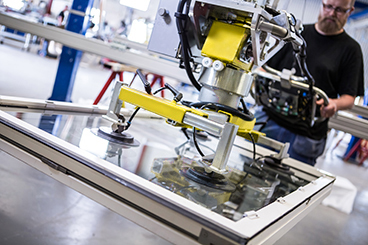

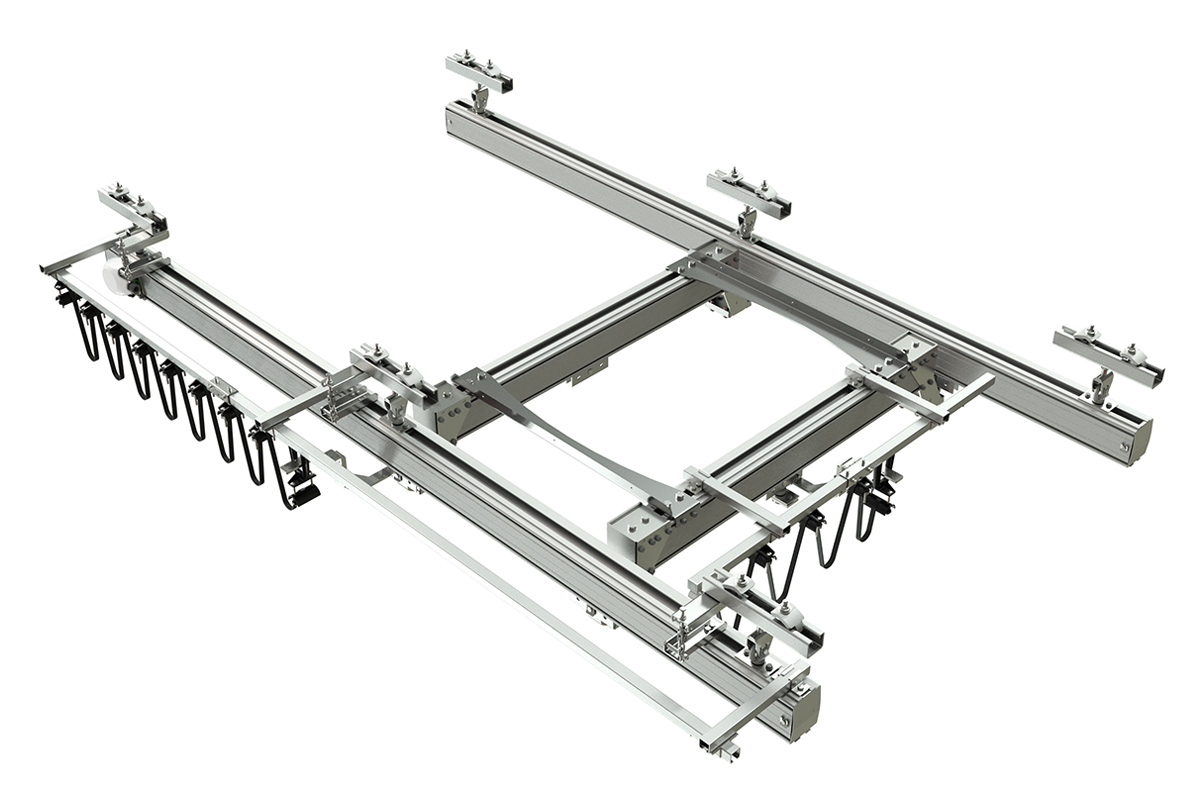

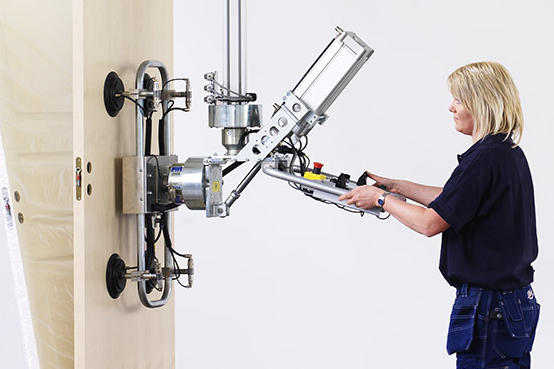

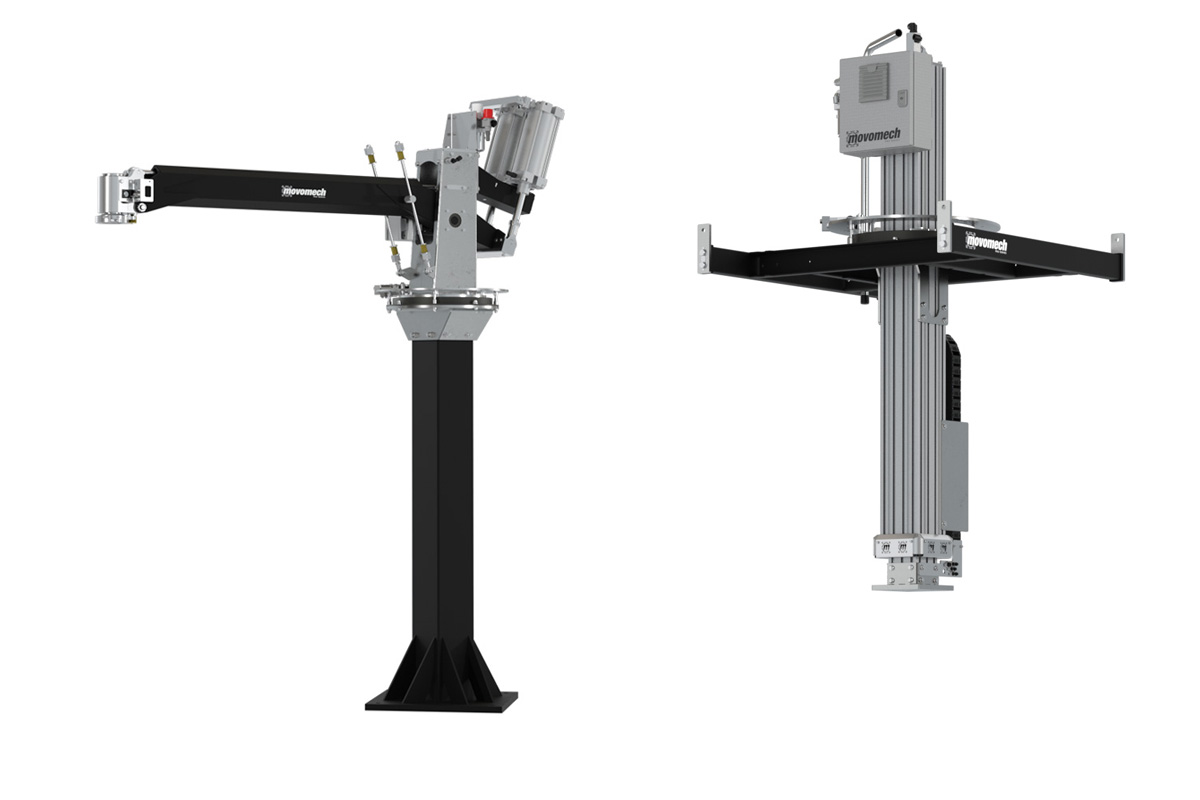

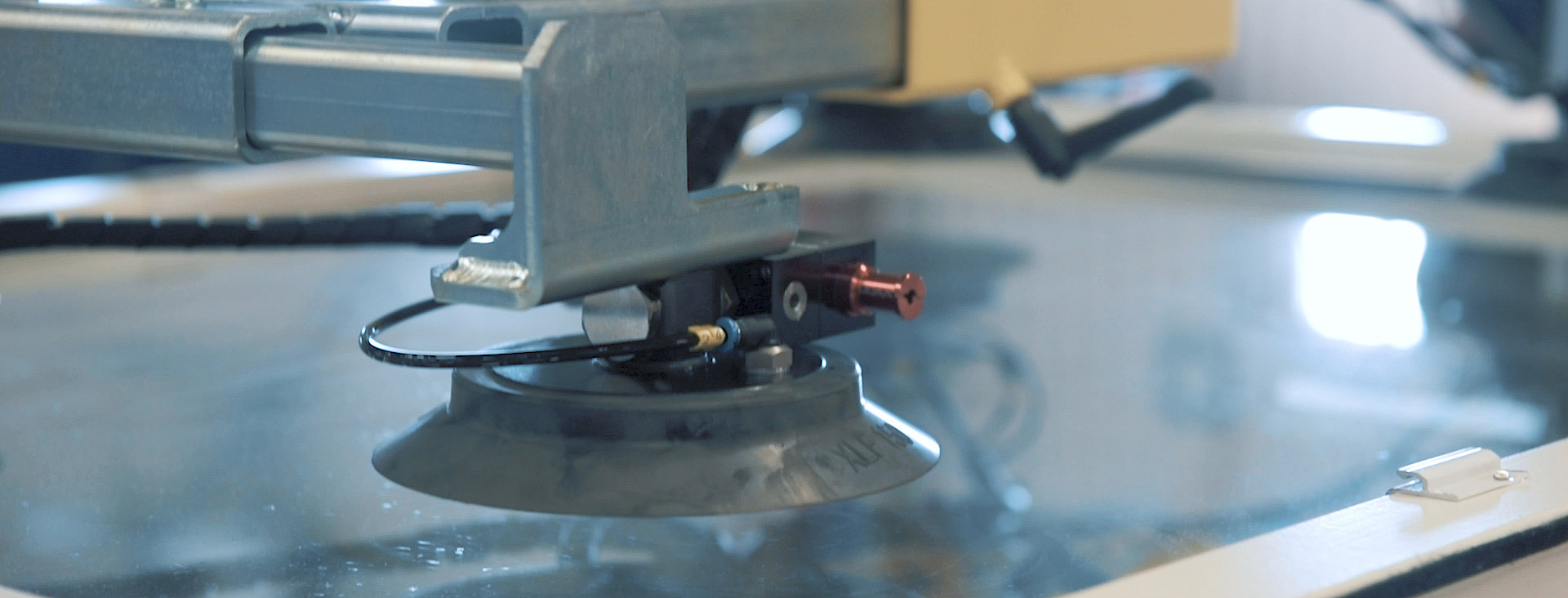

Movomech är en svensk tillverkare av ett brett sortiment av ergonomiska lyfthjälpmedel till industrin – från ett förstklassigt lättraverssystem i aluminium till kompletta systemlösningar för materialhantering med avancerade lyftmanipulatorer och skräddarsydda lyftverktyg.

Lyfthjälpmedel till din industri

Movomechs ergonomiska lyfthjälpmedel och lyftredskap för professionell materialhantering effektiviserar produktionsprocesser och förbättrar arbetsmiljön inom många branscher.

Här är några exempel på hur.

Här är några exempel på hur.

Produktsortiment

Movomech utvecklar och tillverkar produkter inom ergonomisk lyftteknik under egna varumärken sedan 1986.

Referenser

Movomechs produkter och system används inom många branscher och i många länder. Här är ett urval av kunder som valt Movomechföretagen som partner för att effektivisera sina produktionsprocesser. Se fler referenser här!

Vill du veta mer?

Vill du veta mer om Movomechs produkter och system? Fyll i formuläret så hör vi av oss.

English

English

Deutsch

Deutsch

Français

Français